How do you digitalize the right way? – Simple rules for transformation

The rules for a successful Digital Transformation

Properly implemented digitization should lead to less resource consumption and provide more efficient processes to improve businesses. Certain rules must be followed to achieve the best possible result. In this article, you will learn how to digitize your company properly.

Index

Why digitalize at all?

In order to advance into the digital world in a resource-efficient manner, it is first necessary to analyze within the company why one wants to digitize, digitalize or digital transform in the first place.

The big “why” is a central question here – after all, a lot of time and money will have to be invested in such a project before measurable results can be seen.

The outcome of such a project cannot usually be predicted at the beginning and there are numerous variables in the implementation that can all change again and again even during the project. It often takes longer than expected for a process to work digitally and ultimately costs more than planned. All of this also leads to a very high error rate during implementation in practice, which is, however, mostly kept quiet about.

Resource-saving implementation therefore requires a great deal of planning and preparation even before the project is started. After all, the aim is to save time and increase output, and to do this with as little use of resources as possible.

In addition to the actual goal and the why, it must also be defined where exactly to start digitalizing. Companies with several departments, locations and products often have a wide range of options for this.

But how do you choose the right starting point and where does it make the most sense to start digitalization?

Where do you start with digitalization?

Depending on where in a company you start to digitalize, the end results can be different. Every company, every industry and every product is different, so unfortunately there is no universal answer for the “right” digitization. However, there is a certain pattern we can follow in the process. There are best practices and there are clear guidelines from companies that have gone down this path before us.

The simplest method is to select the “biggest domino” in our company or our process – that is, the part that, if it can be solved more efficiently and better, will affect as many other areas of the company as possible and also improve or at least facilitate them in one go.

In this way, by digitizing a single process or area of the company, we achieve the greatest possible output for the least possible input and – as a result – also achieve the greatest degree of sustainability.

This not only conserves resources, but also capital and time.

If a company has not yet digitalized any areas at all, there is usually a central process that spills over into many departments. This can be the processing of quotations, the processing of products and materials, or even sales. All of these tasks pass directly to neighboring departments or usually have such a central function that properly implemented digitalization in these areas must inevitably affect other areas as well.

Digitalization is not a solution to problems

After defining the internal why and the target area in the company, it is now important to understand basic framework conditions in digitization. Older managers in particular often assume that digitalization will immediately make everything better and work smoothly – after all, we have just digitized.

Contrary to what is often assumed: Digitalization is not the solution to all problems. Rather, digitalization is an amplifier of what already exists.

This means that if your basic process that you want to digitize generates errors in everyday life and causes problems for further processing in the company, digitalization will not simply make these obstacles disappear. On the contrary.

Digitizing such a process and increasing output through more efficiency with digital infrastructure would mean that you will get even more of these problems. Instead of getting a better process digitally, you will have to laboriously work through the many problems created by digitalization in the first place.

The desire for more efficiency and better use of human and time resources thus threatens to burst and may even lead to more difficulties and effort than before. Unfortunately, this happens again and again in practice.

Therefore, one rule of thumb applies to effective digitalization:

“If you digitalize crap, you have digitalized crap.”

In order to sustainably improve a process and thus achieve less with more effort, it must not only be digital, but also be improved in the individual process steps. The mere mapping of work packages in software or the relocation of sales structures to a web store system, etc. alone does not result in an improvement.

For this purpose, the basic function of the respective process must be analyzed and checked to see whether it can be solved more effectively using digital aids, for example. There are almost always technical solutions that can help you do things faster, more error-free, more effectively and/or more automatically.

If the process is clearly defined in its work steps, a digital tool can be sought in order to achieve an increase in performance by digital means. However, care must also be taken when selecting the digital tool – because by no means every software and every tool are suitable for every company and every product.

Which digital tool do I use?

If, during this research, we have found processes that can be solved much faster, better or easier using digital tools, the next step is to select the right tool for these areas.

In practice, this is not an easy task, as there are often numerous software providers, all of whom would probably more or less provide you with the desired solution if you asked them directly. However, don’t be fooled, because by far not every software that basically offers a technical possibility for solution is also designed in practice to implement it in your desired form.

Well-known mistakes from the history of digitalization, such as that of Fox Meyer Health, clearly show the differences between a theoretically ideal solution and a solution that is disastrous in practice – and this despite the fact that the world’s leading consultants and software providers all contributed to the project with sufficient budgets.

So when it comes to choosing the right digital implementation, we are faced with what is actually an impossible task: We have to measure the results in a project whose outcome cannot be predicted.

But there is a solution for this too, this time from the world of startups. A start-up has a similarly challenging task ahead of it: it must find a valid business model before the start-up funds are exhausted.

It is impossible to calculate or predict the interplay of markets, customers, competitors, the company’s own product, etc. in this process. As with digitalization, you have to deliver real results for something that is actually unpredictable.

Learning-Testing-Feedback

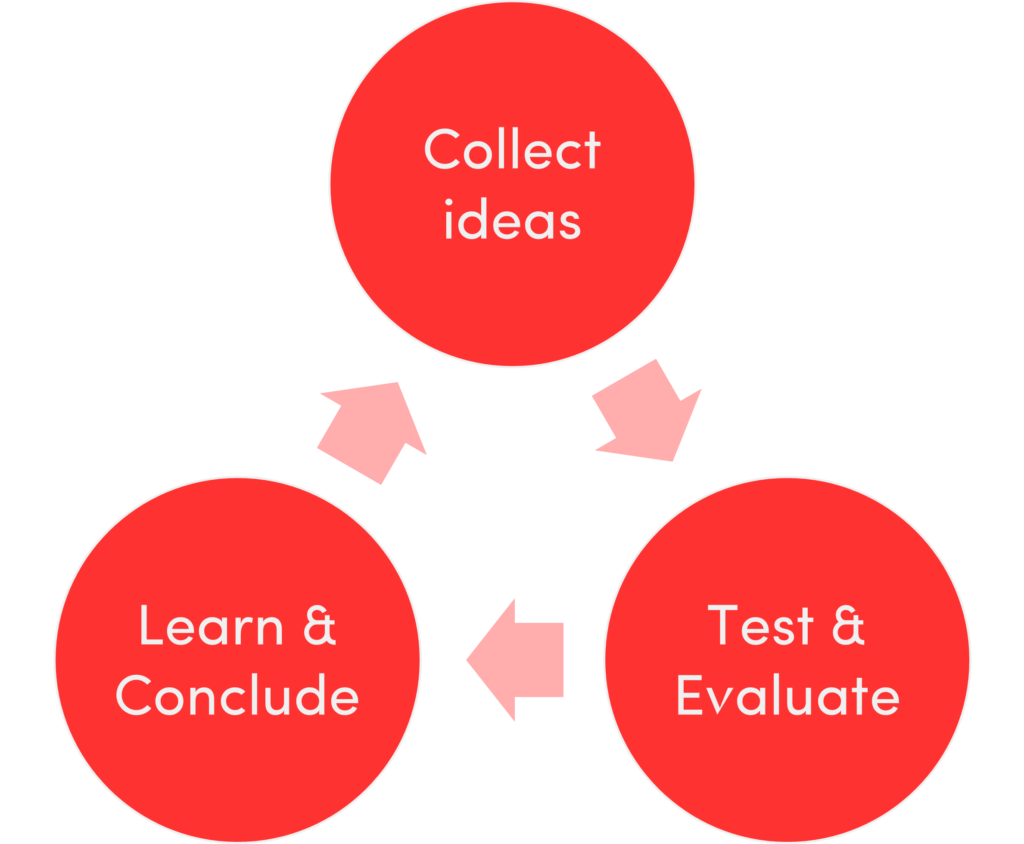

The Lean Start Up movement from Silicon Valley has found a method for this challenging task that allows real feedback to be collected quickly and incorporated back into the process. This allows highly uncertain projects with numerous variables, such as a digitalization of a company, to be implemented as quickly as possible with little risk.

Eric Ries described this in more detail in his book Lean Start Up. In summary, it is about creating hypotheses as quickly as possible, followed by rapid testing with real customers or users to get real feedback from them.

Based on this feedback, the product idea can be improved and adapted to meet the needs of our customers. Then we test again, collect feedback again, and improve the product again, and so on.

The faster this process can be run through, the lower the risk of the project and the more efficiently practical results are obtained.

The process is illustrated by the following figure:

Important! – The time required for the run should be minimized.

As in a start-up, established companies can also use this model as a guide for digitalization and digital transformation. As a result, results are quickly collected on how well their own digitization is received by customers or employees in their day-to-day work, and sources of error can be precisely identified. As a result, this model also ensures greater efficiency and sustainability during and also after the transformation.

Making mistakes allowed

Another paradigm shift is necessary for the most efficient digitalization possible. Most of the time in project management, when goals are missed, a culprit is quickly sought and the project is often stopped or terminated altogether. With digitization, you should be a bit more flexible here and expect problems to arise right from the start due to the complexity. Not everything will work immediately and be applied on schedule.

The old thought patterns according to which mistakes are something bad and must be punished must be put aside for successful digitalization. Even if the big tech corporations sometimes make it seem that way: there is no such thing as quick success, not even in the digital world.

Most breakthrough concepts, software solutions and platforms took several years and had numerous setbacks along the way before they could become the optimized solution they mostly are today.

Remember, digitalization doesn’t solve problems – it amplifies what already exists.

So don’t expect your digitalization project to deliver perfect, flawless results right from the start, either. Setbacks, realignments and problems are not a sign of failure for your digitalization – rather, they are an integral part of the journey.

After all, the more mistakes you make and accurately measure and record stakeholder feedback from them, the more data you have to make that process step better from now on. The more data you collect through the feedback loop, the more accurate and precise your decision-making will be. So give the project and everyone involved some leeway – and communicate clearly that mistakes will not be punished.

Mistakes are a part of this change and a constant companion on this path to optimize a process in the long term.If no mistakes were made, there would be no corresponding feedback to improve the process. Therefore, if mistakes are made again and again in your project, you are probably on exactly the right path to optimize the digital process in the long term.

Exponential growth

However, what exists in the digital world and was previously unknown in the analog world is exponential growth. Properly implemented, it can set processes and systems in motion that produce many times more output – and thus set new standards for sustainability and resource efficiency.

Growth in the linear world meant that, for example, a factory had an output of 100. If you wanted to increase that, you had to build a second factory to get output 200. It took a third factory for output 300, and so on.

But through efficient digitalization, we can do more with what we have. By optimizing workflows and automating individual steps, output increases exponentially rather than linearly. It is therefore entirely possible that an efficiently digitalized company with one factory will no longer deliver output of 100, but 500, 800 or even 1,000.

To achieve this exponential growth, our processes must not only be digital, but optimized to such an extent that we can scale them. This creates the basis for network effects, especially when several departments are gradually fully digitalized. This forms the basis for exponential growth and a sustainable transformation of a company that unleashes unimaginable potential.

Conclusion for efficient digitalization

So, in summary, we start a digitalization with our big, internal why. With this clear objective, we next select the process in the company that will have the greatest possible impact as soon as we digitalize it – we look for our “biggest domino”.

In doing so, we realize that our process must be optimized beforehand and be applicable without errors before we digitize it. After all, we don’t want more of the existing problems, but real optimization. When choosing the right digital tools and software, we realize that the exact outcome is still uncertain at the beginning of the project.

Therefore, we use quick feedback from our users, employees and customers, learn from it and integrate this data back into improving the process in a learn-test-feedback loop.

In this way, we limit uncertainty during transformation. However, we know that surprises can always happen. Therefore, we communicate clearly and openly in our team that temporary mistakes and errors are allowed during the project.

At the end of the project, the reward is waiting for us: the opportunity to grow exponentially through efficient digitalization.

Comments are closed.