Digital Twins explained – Definition and Examples

The digital twin will become increasingly important in the future as a key concept linking the real and digital worlds.

Digital twins are one of the key concepts in digitalization. They comprise the digital representation of real-world (physical) objects for further use in the digital space. In this article, we will explain digital twins, walk through selected use cases, and will also point out a few challenges that have to be observed when dealing with digital twins.

Index

Introduction

When discussing digitalization, and in particular industrial digitalization (e.g. Industrie 4.0), digital twins quickly enter the picture. They are seen as an enabler and key concept for many of the aspects and advantages of digitalization. The core idea of a digital twin is to have a digital representation of a physical object that behaves as its physical counterpart and can be analyzed and used in the digital space to draw conclusions on the real-world object.

The idea dates back to the 1970s when NASA tuned simulation models of an oxygen tank to reflect the conditions of a damaged tank and made corrections to the physical model based on the observations from the simulation.

Today, digital twins cover many more aspects than operational data and simulation. They can serve as the anchor for any digital information that is related to a physical asset.

Digital twin definitions

A quick research easily reveals dozens to hundreds of definitions of a digital twin. Many of those are lengthy and go into great detail, and promote the services of the authoring consulting company. Here, we focus on those from industry consortia, assuming that they represent a view that is agreed on by a representative section of the industry.

Digital twin consortium: A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. (Source)

Industrial Digital Twin Association: Digital representation, sufficient to meet the requirements of a set of use cases. In this context, the entity in the definition of digital representation is typically an asset. (Source)

Industrial Internet Consortium: A digital twin is a formal digital representation of some asset, process or system that captures attributes and behaviors of that entity suitable for communication, storage, interpretation or processing within a certain context. (Source)

These definitions are largely overlapping, with some specific details worth mentioning:

- the object of interest may be a physical asset or also a process

- the digital twin reflects the behavior of the object of interest

- the application of the digital twin depends on specific use cases

The following sections will build on these findings to explain the digital twin. In that context, we will refer to the physical counterpart as the ‘object of interest’, or ‘object’ in short.

Digital twin components and concepts

Components

Derived from the definitions, a digital twin needs to have the following components:

- Data: Available information about the object of interest (real-time or offline)

- Model: a model that can reflect the object’s behavior

- Uniqueness: there must be a 1:1 relation to one particular instance of the object

- Monitor: access to the object’s state

Those components are core to a digital twin and need to be present to count as a digital twin. Other aspects that are typically associated with a digital twin do not necessarily need to be present, since they depend on the use case:

- Analytics: algorithms to analyze the data and behavior of the digital twin

- Simulation: simulation of the model under different conditions

- Control: the ability to interact with and influence the physical object

- Further applications: depending on the use case, the core digital twin aspects can be used in many other ways as required

[Please note: This section is derived from an article by Gartner, which is no longer available on their website]

Concepts

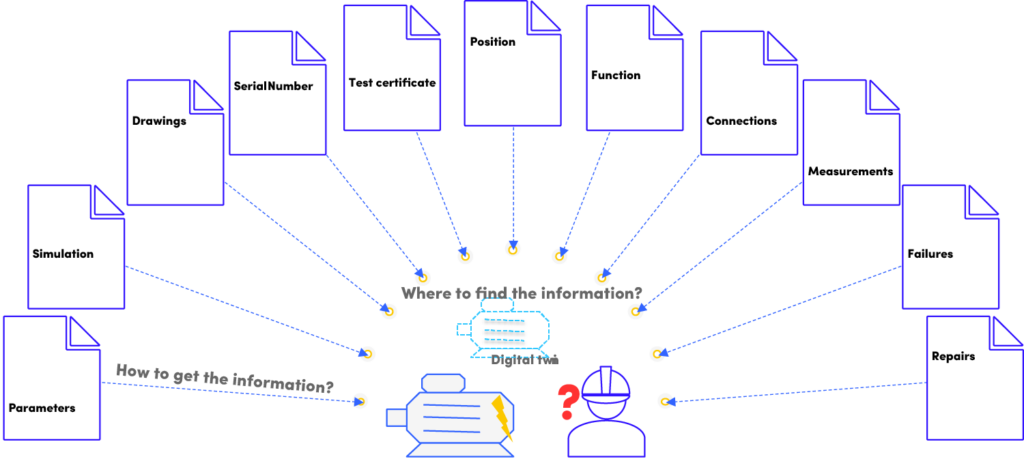

Digital information about an object can be found in a wide variety of formats that are stored and used in a variety of tools, databases, and clouds. In a manufacturing environment, the following list mentions example data and possible storage locations

- real-time information in the IoT cloud, at the edge within the object, or in a manufacturing execution system (MES)

- design information in the product lifecycle management system (PLM)

- commercial information (inventory, orders, deliveries, invoices, etc.) in the enterprise resource management system (ERP)

- service and repair information in the maintenance management system

To make things more complex, some information is available in the supplier’s data space, and some in the user’s. Other parties involved in the object’s manufacturing, delivery, installation, and operation may have further information. All the information is required by the systems and tools that created it and is most efficiently stored in the native format these systems need.

It is therefore questionable if a digital twin of an object should store all the available information within itself, within a digital twin platform. This approach would require exporting the information from the tool database to the digital twin. Local changes to the data could quickly lead to inconsistencies.

But as we will see in the ‘use cases’ section, the value of a digital twin comes from making the information available to different users. Sharing data between all the stakeholders involved in handling an object is an essential advantage. How can this discrepancy between efficient handling of information in the tools that create it, and exchange with other parts for advanced analytics and optimization be solved?

To achieve this, a digital twin concept needs to provide the following capabilities:

- A unique identifier of an object to make sure the different information containers refer to the same thing

- The knowledge of what information is stored where

- Means to access that knowledge wherever it may be stored

The digital twin may also manage information access: for the supplier, the full PLM information may be available, whereas for the operator, only simplified models and published parameters may be accessible. The MES information in turn is within the operator’s domain and fully accessible, and the supplier may only see key performance data without the operational details.

Throughout the lifecycle of a digital twin, it is interesting to note, that the lifecycle of an object very often starts in the digital space. Most products are developed today using engineering tools and simulators before they go into production. In the design and engineering stage, the information generated remains generic, i.e. this information is part of the digital twin of all the objects manufactured from it. Only when an object is being produced, i.e. when the physical twin is generated, the digital twin can refer to one particular object in the real world. The generic, object-type information (engineering drawings, etc.) is then combined with the instance information (serial number, location, operational data, etc.) to form the digital twin.

Standards

Even if the digital twin knows where to find information about an object and how to access it, it may be difficult to actually retrieve it. If the data formats are proprietary and different for each tool accessed, the data conversion effort becomes unmanageable.

Such interfaces and data models have to be standardized in order to allow a seamless exchange of information. Originating from the German ‘Plattform Industrie 4.0’ initiative (Source), one concept to standardize on digital twin data models is the ‘Asset Administration Shell’ (AAS) (Source). These concepts are now being formulated as the IEC 63278 standard. In addition to the general concept of the AAS, some of its sub-models are already released IEC standards (e.g. IEC 62541, OPC UA, data model and exchange standards).

Use case examples

In this section, we will walk through just a few use-case examples. They emphasize the need to exchange data between the information sources to achieve a digital twin value beyond the value of the individual tools.

Augmented repair and maintenance

When equipment fails, the resulting downtime may be costly. It is essential to find a fault, if possible already predicting it before it happens. Once found, the equipment has to be repaired as quickly as possible.

A digital twin of the equipment would have access to the measured data of the equipment in operation, which could then be used to predict an upcoming failure. If that information is shared with the supplier, an equipment expert can remotely analyze the data, and interact with the personnel on the factory floor to get additional observations. The digital twin provides access to the design drawings and simulations allowing the expert to test possible solutions to the problem. Context information, such as where the equipment is installed, what it is used for, and how it performed in the past is also available from the digital twin.

In a typical case where industrial equipment is affected, sending a service technician to the site may be necessary to bring it back to operation. Making full use of the digital twin’s possibilities, augmented and virtual reality can be applied to address the issue remotely. An on-site technician, who is skilled, but not trained in the service procedures of the device in question, may remotely be instructed through augmented reality (AR) glasses. The remote expert can guide the technician through the procedures, indicating the required actions in the AR view of the technician. Additionally, the internal structure of the equipment can be blended into the real object by overlaying the design drawings with the physical structure. Wearing virtual reality (VR) glasses, the remote expert gets a live view of what is happening on-site, can all necessary information provided by the digital twin in a quiet office environment, and can seamlessly interact with the technician to fix the problem without the need of traveling.

The equipment is operational in a shorter time since no travel time was involved, and the remote expert can deal with another case in another area of the world minutes after the first case is closed.

Product optimization

The maintenance technician and the remote expert in the repair and maintenance use case used the information that was created along the lifecycle of the product, to the point where it failed. But also the other direction is possible, that information that is collected in operation is fed back to the organization that designed the product. Product improvements can then be introduced based on real-world experience and data.

If a person responsible for a product (product management, R&D) has full access to all the digital twins of the installed fleet (at least to the information that is released for sharing by the customers), statistical analysis can reveal product weaknesses and improvement potential.

Analyzing the product specifications against the usage patterns measured in operation in various applications could lead to an application-specific design that fits the observed use better than what was specified by the customer’s consultant. Weak parts that cause failures can be reinforced, or parts can be optimized because the design parameters were never met in operation. A more efficient product may finally result, and the success of the measures can again be observed in the digital twins of the modified product.

The feedback from the service reports can also be analyzed, detecting where technicians used most time for the repair. Adapting the design to make service easier will reduce the mean-time-to-repair of future products. If one of the causes of not detecting a failure was missing data, the new design can integrate sensors that will provide the information in the future.

Product management can analyze additional commercial data that is available through the ERP system: to whom was the product sold, where it was finally installed, what services were purchased, etc.

Even if the product organization feeds a lot of information into the digital twin for later use down the lifecycle, having a digital twin that observes and collects the information about the lifecycle is highly valuable to come up with a product that fits the real use much better.

Building construction

Digital twins are not limited to manufacturing. The continuously increasing use of building information management systems (BIM) is a good foundation for the advanced usage of digital twins also in the construction industry.

The BIM information is per se not a digital twin of a building: it lacks the ‘monitoring’ aspect, integrating data from the building for advanced applications. One of these applications can be a near real-time comparison of the construction with the BIM information to report progress, and possibly indicate deviations from the plan. The feedback information can be implementation reports from the workers on site, but it can also be automatically collected information e.g. through autonomous drones passing through the construction site at night and scanning the building. Similar to the repair and maintenance case explained before, the BIM information can be blended into AR glasses to visualize work instructions blended over the work area.

Once the building is in operation, the BIM models support facility management. They can be used to display the measurements from the building automation system in relation to the building, temperatures, occupancy, alarms, etc. In the case of faults, the AR-guided maintenance mentioned before can be applied as well, where lines and pipes in the walls can be displayed interactively when walking through the building.

If a digital twin of the building is consistently used and maintained throughout its lifecycle, building modifications and extensions that are added to the model help to always refer to the right structures and to understand the context in which they were implemented. It is then easier to answer questions such as where critical material was used, or where a sewage pipe is leading to.

Conclusions

Digital twins have one key task: to make all the information about an object of interest accessible from one place, to be analyzed, exchanged, simulated, and used in any other way necessary for any desirable use case. The applications that become possible if information about an object is available consistently in a digital twin are very broad. Adding artificial intelligence (AI) to the analysis and to the optimization even widens the applications and increases the value.

It is to be noticed though, that building and also maintaining digital twins requires investment and discipline. The digital twin is not something that falls from the sky, it requires thorough engineering work to become valuable. Once available, they support decision-making on various levels: operational, tactical, or strategic. The wide range of possible use cases for digital twins suggests first investigating the use cases, and then building the digital twin that best supports these use cases. The application of the standards mentioned in the corresponding section helps to keep the digital twin extendable to cover more use cases over time.

Once available, it opens great possibilities for digitally enhanced products.

Comments are closed.