Deep Learning and AI in the Supply Chain

There is no way around artificial intelligence and deep learning anymore, both in the transportation and logistics industries.

Exploit the potential of logistics. Artificial intelligence is conquering all industries, with incredible potential for automation and numerous docking points for AI-based applications. We can already automate transport and supply chains, optimize traffic flows and increase the security of goods and traffic. In the future, however, even more will be possible. Artificial intelligence in logistics: examples, opportunities, threats.

In our seventh part of the series, “The World of Supply Chain 4.0,” read about the ultimate AI booster – the field of logistics. Artificial Intelligence (AI) is not only conquering all industries, but in the environment of logistics, it has numerous big data sources, countless docking points for AI-based applications and a very high potential for automation.

Did you know that in 2018, more than USD 40Billion was spent on AI research worldwide? Who is still surprised by this, as through quite accurate predictive models and a steadily increasing process efficiency, unprecedented capabilities to changing markets are now possible. Thus one of the most important logistics growth drivers in the coming years. For the non-scientists among us, we prefer to speak of “Deep Learning” or “Machine Learning” instead of AI (Artificial Intelligence) or AI.

Below we will show you some examples of where Artificial Intelligence is being used and how you can already benefit from it today or in the near future. According to a survey by Hermes, about 20% of all companies in the logistics and transport industry currently use AI applications. In the coming years, another third are planning to use AI. Thus, even SMEs with the appropriate expertise are in a position to use the huge possibilities of AI in logistics.

Index

Possible uses of AI in the supply chain

Robitics

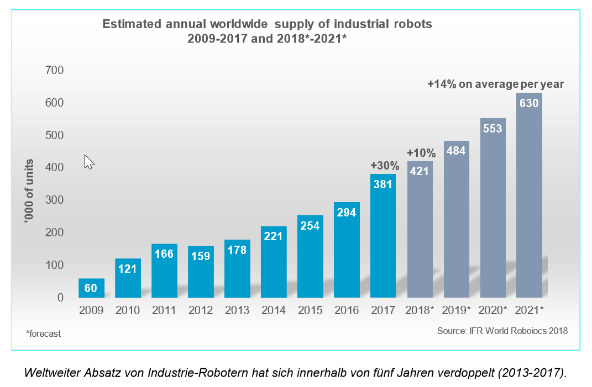

Here, enormous savings potentials for companies are possible. In the IFR (International Federation of Robotics) Report, from October 2018, it shows that robot sales will double in five years. In 2021, it is estimated that global sales will increase by +14% on an annual average, Europe will achieve the greatest robot density worldwide, Japan will produce the most robots worldwide, and China will record the strongest demand and thus the largest sales volume. The IFR report indicates that 73% of the total sales of industrial robots in 2017 will be in five main markets: China, Japan, South Korea, the U.S. and Germany. The largest demand for robots, with a 33% market share (2017), continues to come from the automotive industry. According to the Tractica Research Institute, more than $22 billion in warehousing and logistics robots will flush their manufacturers’ coffers by 2021. Deep-learning algorithms enable robots to make autonomous decisions, such as analyzing and counting goods, identifying them, and manipulating and transporting them.

Autonomous vehicles, drones and ships

We are currently witnessing a head-to-head race between the tech sector and automotive industry, such as Waymo or Apple, when it comes to dominating autonomous driving. The goal is to always make the right decisions in any driving situation, and in the discipline of artificial intelligence to process very large amounts of data, the tech companies are clearly ahead.

-

Estimated annual wordlwide supply of Industrial Robots – Source: IFR World Robotics 2018

Autonomous cargo ships, trucks and drones have long since become more and more part of everyday life and will shape the picture on our roads, as well as on the water and in the air, in a few years’ time. Companies such as Amazon or DHL are already working on international regulatory frameworks to deliver their packages by drone. In the U.S. in particular, AI-controlled prototype vehicles are reeling off mile after mile and becoming steadily more reliable. It is only a matter of time before you see the driverless vehicle next to you on the highway in Switzerland or other neighboring countries, or even sit in it yourself. In a Swiss pilot project called “Line 12”, an autonomous vehicle was integrated into a public transport control system for the first time in March 2018 in Schaffhausen. You can experience this on the Neuhaus Zentrum North and South stops, on a 300-meter circuit.

Predictive analytics

Good predictive tools make it easier for logistics companies to predict machine failures in the sense of predictive maintenance and also to give employees instructions on how to solve the problem, e.g. with regard to demand and capacity planning. Predictive Analytics starts exactly where OLAP (also called Cupe-Operator) or Reporting do not know how to proceed. In this way, they not only analyze the situation but also try to find patterns in the data with the help of algorithms in order to predict similar results in the future. Thus, the logistics industry benefits especially from ki-supported predictive analytics, which becomes a co-decisive cost factor. Early feedback to the user thus ensures that downtimes can be avoided in good time, productivity of logistics facilities can be increased and costs can be reduced. DHL, for example, uses more than 58 different parameters from predominantly internal data sources to develop and optimize a machine learning model in the air freight sector.

Real-time decision making

Make your future decisions in near real-time. For example, automated AI applications compare Zick thousands of freight forwarding providers, schedules and routes. They draw on a myriad of data and information sources to make the best decision in the fastest possible time.

Smart Roads

The data from “Smart Roads” is of immense value to every logistics company, even if this is not immediately apparent at first glance. For example, the company Integrated Roadway, from the USA, which offers real-time forecasts of traffic flows, provides precisely such data information. Benefits include reduced travel times.

Visual AI

A so-called “computer eye” offers significant added value to the logistics industry. For example, this can classify a fault and detect damage considerably faster than a logistics inspector. IBM-Watson, one of the world’s famous AI users, for example, detects and finds damage to train containers through many training sessions. Watson was fed thousands and thousands of wagon photos to classify train containers within a very short time, with a hit rate of over 90%. (e.g. OCR)

Intelligent warehouses

In order to significantly increase the productivity of a warehouse, so-called smart warehouses can be used with the help of AI to save personnel costs as well as enormous potentials of energy and heating costs, for example through the use of smart grids. One of the key benefits that AI can bring to warehouses, thereby reducing increased storage costs, is the reduction of storage space. Which goods should be stocked in which logistics warehouses, for example, is taken into account by the software, which prescribes AI algorithms to determine the necessary consumption behavior of different goods at different locations. In this way, demand accuracy can be ascertained as to which products need to be stocked more in rural areas or more in areas close to the city.

Vehicle telemetry

The treasures of vehicle fleet telemetry data hide such hidden potential. By now, all logistics companies have probably long been equipped with state-of-the-art navigation systems to get their trucking fleets from point A to point B in the most efficient and fastest way possible. AI-supported systems optimize the real-time simultaneous routes and thus orders of their drivers. With those coordinating skills, what human can keep up? Let alone handle large fleets smoothly? All those who are already using these innovative AI systems today are gradually gaining a clear competitive advantage and will benefit from it in the long term.

4 key trends in the logistics sector

These key trends are driving the digital revolution in the logistics sector. Will they soon replace humans?

1. Technology

IoT, AI and Blockchain will prevail as the key trends in logistics in the long run. The reason is their sustainability, which has a positive impact on the price-performance ratio.

2. Customer orientation

The eCommerce sector will continue to grow steadily and solidly, especially the B2B sector. This will make omnichannel solutions indispensable. The customer wants more and more convenient and faster logistics solutions.

3. Sustainability

Due to the ever stricter regulations to reduce CO2 emissions, logistics companies are obliged to think and act in a resource-saving way. Green energy logistics – successive electrification of fleet and logistics facilities offer the potential for more environmentally friendly logistics processes in the future.

4. People

Despite the redefinition in personnel structures, due to automation, robots, etc., the human being will continue to play the important and central role in the logistics industry. It will be pleasing for him that the mainly physical and demanding activities will be supported step by step by new technologies.

The interplay between AI and logistics

AI and logistics go extremely well together. There is hardly an area in the economy that has so much potential to optimize existing workflows and processes so comprehensively.

And it is precisely this that most specialists and managers have the greatest fears about. Will this make people completely superfluous in the short or long term? No, absolutely not! – Artificial intelligence will not make human work superfluous, but much more likely to reshape it. Nevertheless, according to the Logistics Trend Index (Messe München), 70% of all specialists and managers are more dismissive than open to the topic of AI.

A recent report from DHL on digitalization in the supply chain reveals in a survey that of nearly 350 supply chain and operations professionals, 95% are not taking full advantage of the potential benefits offered by physical, informational and analytical innovations. A great deal of education and training is still needed in this area.

Comments are closed.